Sep 15, 2020

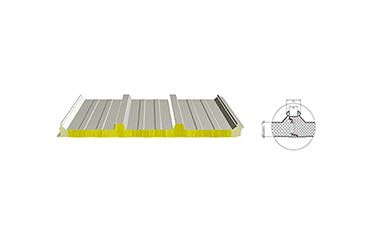

Sandwich Panel is a polyurethane thermal insulation sandwich panel for construction, also known as leak-proof sandwich roof panel, polyurethane rigid foam insulation board, polyurethane composite board, PU board, etc.

It is a kind of high-efficiency and energy-saving building envelope material with a wide range of uses and great potential. It is also a new type of energy-saving board promoted and promoted by the Ministry of Construction.

The building material is a composite board with rigid polyurethane foam as the thermal insulation layer, which is mainly used in industrial kitchens, logistics storage, roofing and maintenance systems of integrated houses.

1 Overview

Anti-leakage sandwich roof panels, polyurethane rigid foam insulation panels, polyurethane composite panels, PU Sandwich Panels are popular terms for polyurethane sandwich panels.

Strictly speaking, it should be a polyurethane insulation sandwich panel for construction. The national standard is GB/T 23932-2009, and the old standard is JC/T868-2000.

2. Purpose

This product is a bimetallic, single-metallic, and non-metallic composite sheet with polyurethane rigid foam as the insulation layer. It is usually used in the wall and roof enclosure systems of industrial plants, logistics storage, and integrated houses.

3. Construction technology

The production of polyurethane sandwich panels requires an advanced continuous production line of sandwich panels. The process is cold bending forming of inner and outer galvanized (aluminum-zinc) color steel plates, and a composite of polyurethane hard foam coated in the middle.

The use of patented anti-leakage sandwich roof panels takes advantage of the polyurethane sandwich panels to the extreme.

Sandwich Panel

4. Performance characteristics

This product has the following characteristics:

1) Low thermal conductivity Polyurethane sandwich panel composite panel has low thermal conductivity and good thermal insulation performance. It is currently the best insulation material.

2) Beautiful board shape and convenient installation

3) Polyurethane sandwich panel has good fire resistance

4) The polyurethane sandwich panel is non-toxic and tasteless

5) Wide operating temperature range

6) Waterproof and moisture-proof

5. Summary

The polyurethane sandwich panel has a beautiful appearance and a good overall effect. It integrates load-bearing, heat preservation, fire protection, and waterproofing.

There is no need for secondary decoration, installation is quick and convenient, the construction period is short, comprehensive benefits are good, and it has a good cost-effective advantage.

It is a kind of high-efficiency and energy-saving building envelope material with a wide range of uses and great potential. It is also a new type of energy-saving board promoted and promoted by the Ministry of Construction.

6. Scope of application

Polyurethane sandwich panels are mainly used in roofing and exterior walls of industrial plants and warehouses.

7. Purification project

With the continuous progress of society, industries such as electronics and medicine are developing rapidly. In the manufacturing process of products in these industries, it is necessary to provide a clean production environment.

Color-coated sandwich panels are not easy to adhere to dust, easy to clean, and have fewer joints. Therefore, sandwich panels are widely used in production and working environments that require cleanliness as interior walls and ceiling materials.

Applications include electronics and computer product manufacturing, medical supplies and pharmaceutical production, aerospace, precision instrument manufacturing, food production, medical operating rooms, and other industries.

Although some workshops do not require high cleanliness, in view of the flexible disassembly and assembly of sandwich panels, polyurethane sandwich panels are also used as partition walls inside the workshop.