Aug 24, 2020

Polyurethane sandwich panels are widely used in factories, warehouses, office buildings, and other projects for their convenient and fast installation, heat insulation, fire protection, environmental protection, beautiful appearance, and light unit weight.

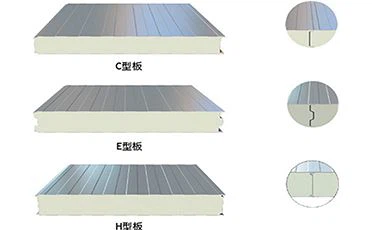

The plate is composed of inner and outer steel plates and core materials. The outer steel plate is generally 0.6 thick, and the inner steel plate is generally 0.4 or 0.5 thick steel. The surface form of the outer steel plate is generally divided into three types: pure flat, small corrugated and embossed 6 kinds of effects (pure flat and small corrugated are best, many owners like to use a pure flat plate); the core material generally uses rock wool, glass wool or Polyurethane material is made by mechanical compounding.

PU Sandwich Panel installation process:

Material arrival and unloading→determination of starting board elevation and axis→installation of flooding plate and pallet→installation of sandwich panel→installation of vertical metal moldings→installation of door and window edges→installation of parapet caps and Gluing construction → tearing off the protective film.

1. Material arrival and unloading

The on-site stacking site should be level and hard, and the road can meet the requirements of transportation vehicles. For every 10,000 square meters of metal plates, about 1,000 square meters of storage space is needed. When hoisting, the board in contact with the sling should be protected by a soft appliance. For long-length sandwich panels, three-point lifting should be used, and a pole should be used for the upper part.

Note: When stacking polyurethane edge-sealed rock wool boards, in order to be foolproof, you must prepare enough plastic cloth to prevent rain, because the rock wool boards and glass wool boards that have not been installed will cause the core layer to be damaged after long time absorption.

Pu Sandwich Panel

2. Confirmation of purlin

1. Confirm whether the purlins are installed in the same plane

2. Whether the verticality or displacement of the purlin on the axis is too large

3. According to the design, mark the vertical ink line at the joint of the flashing plate and the pallet on the purlin.

3. Installation of flashing plate and pallet (some companies integrate flashing plate and pallet, and some pallets are metal steel plates)

1. Install the flooding plate and pallet according to the elevation line, and pay attention to the use of the liner.

2. Installation of yin and yang corner corners, (some companies use metal corner plates, factory cut 45° angle, on-site processing)

3. Install the inner longitudinal joint metal strip according to the ejected ink line, and pay attention to sticking the sealing tape and the insulation strip. (Some companies don't need metal strips for inner longitudinal joints, but directly plug insulation strips).

4, The installation of sandwich panels

1. Lift the sandwich panels of the corresponding specifications in place according to the layout drawing, and use special spreaders for vertical transportation of the panels.

2. Install sandwich panels from bottom to top. For sandwich panels that need to be cut, the iron filings should be cleaned up after cutting to prevent rust.

3. Use self-tapping nails to fix the polyurethane sandwich panel on the purlin. Pay attention to the nailing strength and not tighten the screws too tightly to prevent the deformation of the fixing plate and damage the waterproof gasket of the screw itself.

4. Paste waterproof seals and sealant on both ends of the Sandwich Panel to prevent rainwater from flowing into the board along the transverse seams.

Follow the above sequence to install the sandwich panels.

Note: Before installing the metal plate, be sure to tear off the protective film at the mouth of the package, otherwise it will be difficult to remove it clean in the future.

5. Installation of metal moldings and other processes

1. The protective film on the metal plate to be installed should be torn off before installation.

2. For the installation of the outer metal molding, pay attention to the use of the liner at the overlap, and paste the sealing tape on both sides and seal the glue.

3. Connect the inner and outer metal inserts together with screws.

6. Gluing construction of outer metal inserts

1. Before gluing, apply masking paper to the construction site and stuff insulation cotton in the molding.

2. Glue and repair and flatten.

3. Tear off the protective film.

We are Sandwich Panel supplier, if you are interested in our products, please feel free to contact us.

Previous: Why Prefabricated Buildings Are The Best Choice For Your Business?

Next: Advantages And Disadvantages Of New Eps External Insulation Materials