Sep 03, 2020

Polyurethane composite panel

Polyurethane composite panel is also called PU Sandwich Panel.

The composite board with polyurethane as the core material is composed of upper and lower color steel plates and intermediate foamed polyurethane. It adopts the world's advanced six-component online automatic operation mixing and casting technology, which can complete the proportioning and mixing process of social batching centers or factories online at one time. It can also be adjusted online at will according to the temperature, so as to produce distinctive high-strength, energy-saving, and green building boards.

Sandwich Panel

Because of its good fire-proof and moisture-proof performance, it is also often used as the edge-banding core material of other material composite panels. The polyurethane edge-banding composite panel uses high-quality color coated steel plate as the surface material, continuous rock wool and glass wool as the core material, and high-density hard The foamed polyurethane is filled with tongue and groove, after high-pressure foaming and curing, the cotton cloth is automatically densified and made of super-long double-covered belt control molding compound. Compared with traditional cotton maintenance materials, it has better fire resistance and heat insulation effect and longer performance, Easy installation, elegant appearance. It is a leader in steel building maintenance materials.

It is generally used for the outer roofing of buildings. Sandwich Panel has good heat preservation, heat insulation, and sound insulation effects, and polyurethane does not support combustion, which is in line with fire safety. The combined effect of the upper and lower boards with polyurethane has high strength and rigidity. The lower board is smooth and flat, with clear lines, which increases the indoor beauty and flatness. Easy to install, short construction period, and beautiful, it is a new type of building material.

Sandwich panel has lightweight, beautiful appearance, and good corrosion resistance, and can be directly processed. It provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, and electrical industry. Good results such as wood, efficient construction, energy-saving, and pollution prevention.

As a new type of building energy-saving insulation materials, polyurethane composite panels have been widely used in different countries. Its use plays an important role in promoting the continuous innovation of building materials. With the modern requirements of the construction industry, It is getting higher and higher, especially for the use of indoor materials. Therefore, the choice of polyurethane composite board is a general trend.

PU Sandwich Panel

Scope of application

As a building energy-saving insulation material, polyurethane composite panels have been widely used in developed countries such as Europe, the United States, and Japan, with a penetration rate of 80% and less than 10% in my country. Polyurethane sandwich panel is an excellent energy-saving insulation material, and its excellent heat insulation, fire resistance, and heat preservation performance can provide an efficient solution to China's energy consumption crisis.

Polyurethane sandwich panels are widely used in large industrial plants, cold storage, garages, mobile homes, exhibition halls, exhibition halls, stadiums, shopping malls, airports, power plants, villas, hospitals, stratum and high-rise office buildings, etc., due to excellent thermal insulation The performance is mainly applied to the roofs and walls of industrial and civil buildings.

Insulation performance

Class A polyurethane composite panel has excellent thermal insulation performance

The 5cm-thick composite board is equivalent to the 1m-thick concrete thermal insulation effect and has excellent thermal insulation performance.

Polyurethane rigid foam is a new type of polymer material with excellent properties of small bulk density, low thermal conductivity, high closed cell rate and corrosion resistance

Air tightness

Roof panel advantages

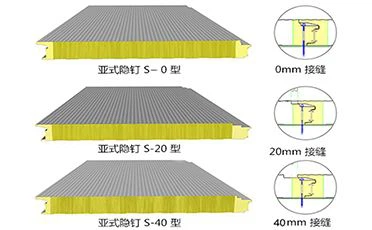

The polyurethane roof panels are connected by concealed nails, and the panels are tightly overlapped.

The unique waterproof tank design effectively prevents rainwater from infiltrating and avoids the phenomenon of cold bridges.

The wave height of 40mm greatly improves the bearing capacity of the roof panel. While ensuring the insulation effect of the building, it effectively reduces the customer's construction cost, and the roof slope can reach as low as 3%.

Advantages of wall panel

Concealed nail connection, no exposed screws on the surface, beautiful and smooth building walls.

Very high flexural bearing capacity, superior wall mechanical properties, reducing dependence on auxiliary steel structure.

Excellent thermal insulation performance, reducing the cost of building indoor air-conditioning equipment.

Various appearance effects, beautiful walls.

Technical advantages

*Efficient insulation

Grade A composite board has the lowest thermal conductivity of organic thermal insulation materials (≤0.022). A grade-A polyurethane composite board with a thickness of 5cm is equivalent to the thermal insulation effect of 1m thick concrete. Grade A polyurethane composite board is an ideal insulation product to achieve 75% of my country's building energy-saving goal

*Super flame retardant

Class A composite board will not burn through after 30 minutes of flame at 1000℃.

*Durable weather resistance

Grade A composite board has been tested for weather resistance for more than 6 months, and its various performances are stable and can be used for the same life as the building.

*Good dimensional stability

The compressive strength of the A-grade polyurethane composite board is above 200kp, and the board has good temperature resistance and no deformation.

*Low carbon environmental protection

Class A polyurethane composite board uses bio-based raw materials, fluorine-free foam, does not use harmful substances prohibited or restricted by the state and is environmentally friendly.

We are the Sandwich Panel supplier, if you are interested in our products, please feel free to contact us.